Approx. read time: 5 min.

Post: China’s Stainless Steel Breakthrough in Hypersonic Missile Technology

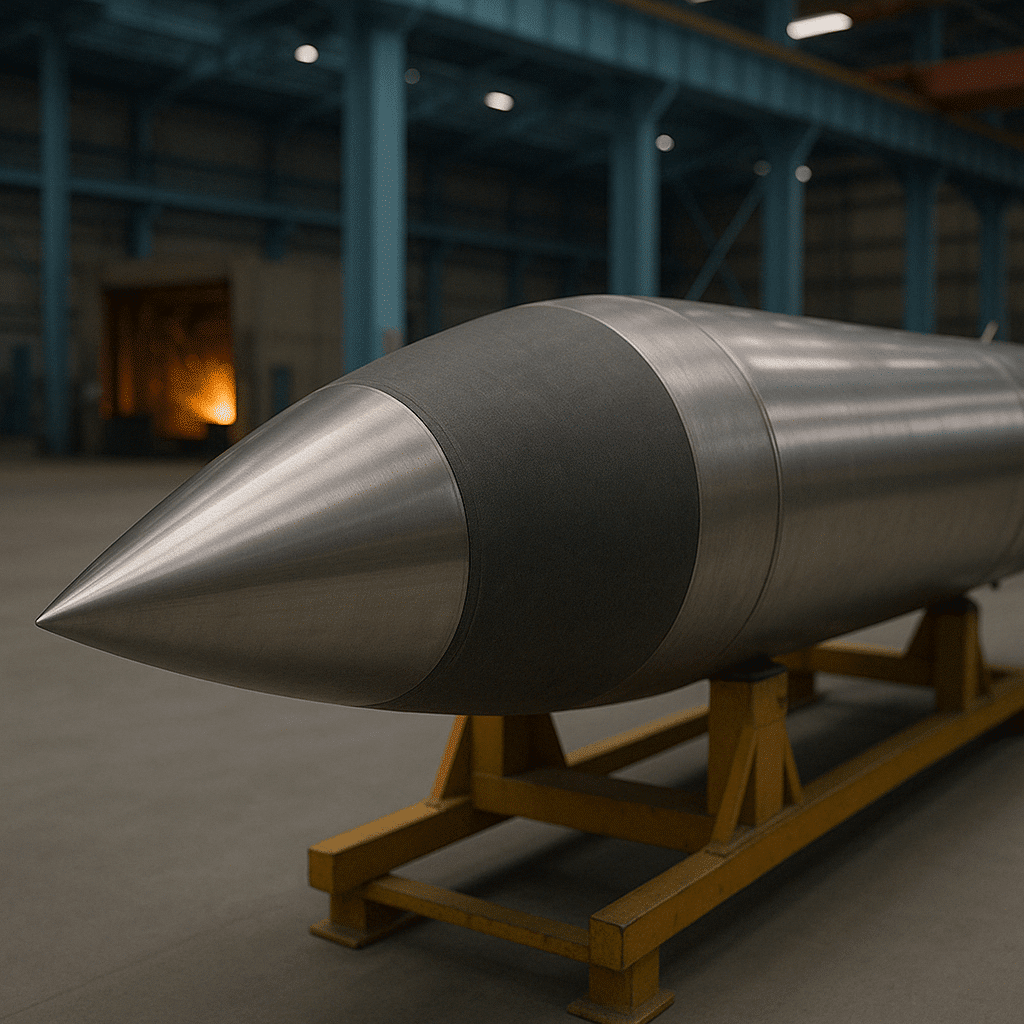

China Redefines Hypersonic Warfare with Stainless Steel: A Breakthrough Once Thought Impossible

A Revolution in Aerospace Engineering

In a stunning leap forward for aerospace engineering, Chinese scientists have turned the impossible into reality by developing a hypersonic missile component using stainless steel—a material long dismissed by engineers and defense experts as unfit for the task. This material, known for its durability in industrial settings but limited thermal resistance, is now proving capable of withstanding the brutal conditions of Mach 8 flight, roughly 9,800 km/h (6,090 mph).

The breakthrough, spearheaded by Professor Huang Fenglei and his team at the Beijing Institute of Technology, isn’t just a milestone in materials science. It’s a major step toward revolutionizing the cost structure of hypersonic weaponry, previously locked behind rare, ultra-expensive materials like tungsten.

A Personal Reflection on Cost Constraints

Years ago, I worked on a multi-phase robotics project for an industrial automation challenge. We designed a heat-seeking end-effector that required sustained performance near induction ovens. The problem? We needed custom parts that could survive exposure to intense heat for extended periods—something we could only achieve using titanium or tungsten-based alloys. Not only were these materials hard to find locally, but the cost also exceeded our entire material budget. We ended up shelving the project for months.

That experience left a lasting impression on me: the biggest barrier to innovation isn’t always knowledge or skill—it’s access to the right materials. That’s why this Chinese breakthrough hits so hard. It’s the ultimate workaround for cost and supply chain limitations, built not from exotic innovation, but from refining what’s already widely available.

Why Stainless Steel Was Never an Option—Until Now

Traditionally, hypersonic missile components like nose cones and heat shields have relied on tungsten alloys, thanks to their incredible melting point of 3,422°C and strong structural integrity under stress. These properties made them indispensable in environments where surface temperatures can exceed 3,000°C.

Stainless steel, in contrast, begins to soften around 1,200°C. That made it a non-starter in any high-Mach application—until now.

So how did this team make stainless steel viable?

Engineering Ingenuity: The Thermal Shield System

To overcome this temperature limitation, Professor Huang’s team implemented a layered thermal protection system:

- Layer 1: Ultra-High-Temperature Ceramic Coating — Resists direct surface heat and dissipates thermal spikes.

- Layer 2: Aerogel Thermal Insulation — A 5mm layer of lightweight, ultra-low-conductivity aerogel dramatically slows heat transfer.

- Layer 3: Stainless Steel Core — Maintains shape and strength, protected by the layers above.

This solution essentially decouples the outer heating problem from the structural demands of the missile body. The stainless steel doesn’t need to resist the heat directly; it just needs to hold firm within its protective cocoon.

The result? A nose cone that can survive hypersonic flight at Mach 8, with cost savings of 60–80% over traditional tungsten-based parts.

Why Mach 8 Matters

Hypersonic missiles operating at Mach 8 (9,800 km/h) experience extreme friction with air molecules, generating heat so intense it can vaporize conventional metals. Temperatures can surge beyond 3,000°C, rivaling those seen during spacecraft atmospheric reentry.

Being able to shield a missile nose cone at these speeds using a common alloy like stainless steel is no small feat. It’s like building a race car that wins Le Mans using parts from a daily driver—with a clever engineering twist.

Strategic Implications for China’s Defense

This innovation marks a significant shift in global military dynamics. The Chinese military, particularly the People’s Liberation Army (PLA), is now integrating stainless steel components into its hypersonic arsenal. This reduces costs, increases production speed, and bypasses the need for foreign or rare materials.

From a geopolitical standpoint, this development enables:

- Mass production of hypersonic weapons

- Reduced dependence on rare earth and heavy metals

- Expanded technological independence

- Rapid iteration and testing cycles

If tungsten was once the gatekeeper of hypersonic technology, stainless steel just kicked the gate wide open.

A Ripple Effect Beyond the Battlefield

Though born in the defense sector, the implications of this breakthrough are far-reaching. Any field requiring extreme heat resistance could benefit:

- Aerospace & Spaceflight: Reusable spacecraft, orbital reentry systems

- Energy Sector: Nuclear containment, turbine blades, fusion research

- Advanced Manufacturing: Industrial robotics, chemical plants, smelting furnaces

Even commercial sectors could eventually incorporate scaled-down versions of this technology in high-efficiency thermal insulation, heat shielding, or extreme climate architecture.

What’s Next in Materials Science?

The success of this stainless steel-based solution has paved the way for further exploration into next-gen materials. Chinese researchers are reportedly testing:

- Smart alloys with adaptive heat resistance

- Nano-structured stainless steels

- Self-healing composite materials

- Advanced aerogel variants with even lower thermal conductivity

These developments may soon unlock materials that were once confined to science fiction.

Conclusion: The Future Was Hidden in Plain Steel

This isn’t just a story about a missile, or even a breakthrough in metallurgy. It’s a story about challenging assumptions and proving that innovation doesn’t always need to start with exotic resources. Sometimes, the key to progress is asking the right questions about the materials we already have.

What China has done here isn’t just technical wizardry—it’s a practical, strategic, and philosophical statement.

“The possibilities aren’t just endless. They’re already here—we just need to unlock them.”

This may very well be the beginning of a new age in both defense technology and industrial science. And it all started with a humble metal that engineers around the world had written off.

Related Videos:

Related Posts:

The Emotional Heart: How Far We Go to Protect It

Global Tensions Rise: Iran’s Direct Attack on Israel and the International Repercussions

AI-powered thermal cameras could be used to crack your passwords

Cyberattack Targets ThyssenKrupp’s Automotive Division: A Swift Response to Secure Operations

Revolutionizing Wearables: OnePlus Watch 2 Aims for Superior Battery Life and Design Innovation

3D Printing: Applications Beyond Prototyping – Revolutionizing Production Across Industries