Approx. read time: 14.9 min.

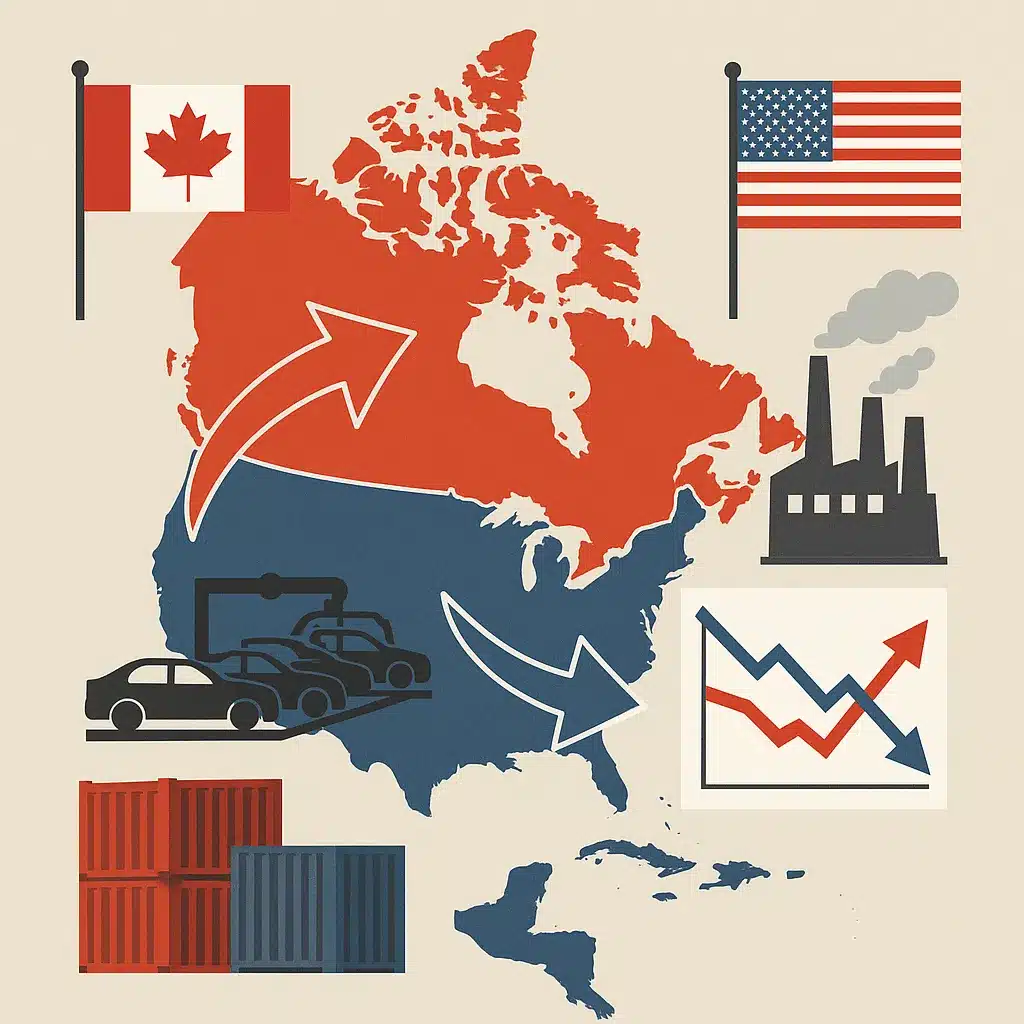

Post: Stellantis Pulling Investments Out of Canada: 10 Impacts

Stellantis Pulling Investments Out of Canada: 10 Impacts Canadians Need to Know

🔎 (What changed this week)

Stellantis announced a $13 billion plan to expand production to in the United States. As part of that plan, Jeep Compass production will move from canada Brampton, Ontario to Belvidere, Illinois, with Canadian leaders warning of job losses and threatening legal action tied to prior commitments. U.S. tariffs under President Donald Trump are a key driver, and Canada’s long-standing productivity slump makes us a softer target when global automakers localize supply chains.

🔧 Why Stellantis is pulling investments out of Canada now

Stellantis is shifting part of its North American footprint to the U.S. with a $13 billion program that adds five models and ~5,000 jobs in Midwestern factories over four years. Analysts say the move hedges against tariffs and aligns production closer to the U.S. sales base.

Two immediate reasons stand out:

- Tariffs and policy risk. Reuters reports the company is adapting to 25% tariffs that hit vehicles imported into the U.S. from Canada/Mexico, pushing management to localize more content stateside.

- Industrial policy gravity. U.S. leaders are openly pressuring automakers to “build at home.” Ontario’s Premier publicly blamed President Trump’s stance as a factor behind Stellantis’ decision and urged Ottawa to retaliate if tariff talks fail.

🚗 What exactly is moving

The headline change: Jeep Compass production that had been slated for Brampton will now be built in Belvidere, Illinois, with timing tied to Stellantis’ new program rollout. Union and local officials in Ontario flagged potential job losses and broken commitments; Ottawa says it may threatens to sue stellantis and pursue legal options if contractual obligations aren’t met.

🧱 Tariffs, localization, and Trump’s pressure

Stellantis’ U.S. package was praised by investors as a rational response to tariff exposure and a way to stabilize margins in its key market. More than 40% of its 2024 U.S. sales were imported and thus tariff-exposed — a clear profit risk without localization.

Canadian media and unions framed the shift as Canadian jobs being “sacrificed on Trump’s altar,” capturing how quickly industrial policy can rearrange supply chains across the border.

🧩 What stays in Canada

Not everything is leaving. Stellantis and LG’s NextStar Energy battery JV in Windsor is real and advancing (modules started in late 2024; cell ramp through 2025). The company also signaled a third shift in Windsor while Brampton’s longer-term product is “under further negotiation.” Canada retains important pieces of the EV supply chain—if we can make them competitive.

🛠️ The Ontario ripple effect (jobs, suppliers, municipalities)

Moving a nameplate doesn’t just affect an assembly plant; it hits:

- Tier-1/2 suppliers (stamping, interiors, electronics).

- Tool-and-die shops that are already margin-squeezed.

- Municipal tax bases and local service economies around Brampton.

Global News and CityNews estimate thousands of jobs are at risk, which matches typical multiplier math (1 final job ↔ multiple supplier jobs).

🧠 Is the U.S. pulling Canadian talent? (healthcare example)

Since COVID, demand for nurses and clinicians exploded in the U.S., with robust nurse migration persisting through 2024 per CGFNS. Canada’s TN visa pathway makes the southbound move fast for RNs.

At the same time, Ontario’s nursing register is growing, not shrinking: the College of Nurses of Ontario reports more total nurses in 2025 and solid new registrants in 2024—so it’s a complex picture. Pay and staffing conditions drive churn; some leave the profession, some move provinces, others go to the U.S. for better pay.

Bottom line: There is competitive pressure for Canadian talent (especially in healthcare), but we’re also adding nurses domestically. The key is retention (ratios, pay, conditions), not just recruitment.

📉 Canada’s output and efficiency problem (the data)

Canada’s productivity slump predates 2025 and is now biting harder:

- Labour productivity fell 1.0% in Q2 2025; unit labour costs ticked up. (Statistics Canada)

- Multifactor productivity dropped 1.7% in 2023. (Statistics Canada)

- Investment per worker was only 85% of 2014 levels as of 2023, per the OECD. (OECD) production from Canada to USA

Meanwhile, the U.S. posted +3.3% non-farm productivity in Q2 2025, highlighting the competitiveness gap. (Bureau of Labor Statistics)

.

📊 Fast comparison – Stellantis pulling investments out of Canada

| Metric | Canada | United States | Source |

|---|---|---|---|

| Labour productivity, Q2 2025 | -1.0% (QoQ annualized) | +3.3% (QoQ annualized) | StatsCan; BLS |

| Multifactor productivity, 2023 | -1.7% (YoY) | — | StatsCan |

| Business investment per worker | 85% of 2014 level (as of 2023) | Higher trend vs Canada | OECD |

Context from Bank of Canada: we need to “break the glass” on productivity—competition, innovation, and execution matter. (Bank of Canada)

.

🗣️ Language barriers & workforce integration — nuance, not blame

Language gaps can hurt team safety and throughput in complex environments. Canadian research shows language-related misunderstandings affect performance and safety, especially in technical settings—hence the need for structured workplace language training.

But Canada also invests heavily in LINC/CLIC and Enhanced Language Training (ELT/OSLT) programs to fix this problem. The solution is better onboarding and upskilling, not scapegoating. (Canada.ca)

💸 Wage subsidies: myths vs facts

You may hear, “The Liberal government pays companies to hire immigrants instead of Canadians.” The reality is more mixed:

- There are wage-subsidy programs open to employers (e.g., student work placements, some newcomer integration pilots), but they’re generally eligibility-based, time-limited, and not designed to replace Canadians.

- Some sectoral programs help integrate skilled newcomers and offset initial onboarding costs (e.g., ICTC’s Pathways). This is about filling gaps and improving productivity, not automatic preference over citizens.

- AFP Fact-Check has flagged blanket “kickback” claims as misrepresentations.

Takeaway: Subsidies exist across many groups (youth, students, displaced workers, newcomers) to fix labour mismatches. The competitiveness game is about skills and processes, not who your passport belongs to.

⚙️ Quality, safety and the “Big 3” — separating heat from light

It’s fair to say quality across legacy automakers has been uneven. For instance, Ford led recall counts through mid-2025; Stellantis and GM also faced high-profile campaigns. Recalls aren’t proof of “unsafe companies,” but they do show systemic execution issues in design/change control and supplier oversight.

And initial quality rankings swing by year: J.D. Power’s 2025 study placed Lexus #1 and Nissan #2, while the top U.S. mass-market spot went to Nissan with Chevrolet #3—reminding us how hard it is to keep consistency.

Your 20-year industry point is heard: shortcuts anywhere in PPAP/APQP, line discipline, or supplier validation will show up months later as recalls or warranty costs.

🇨🇳🇯🇵 The competition Canada and Detroit underestimated

Japan won with lean and quality; China is now combining cost, speed, and EV scale. If we don’t execute at their level, localized U.S. plants will cherry-pick the highest-margin work and leave Canada with fewer assembly programs.

🧭 What Canada can do now (policy levers)

- Lock in reciprocity on tariffs (or carve-outs) tied to continental EV/ICE supply chains.

- Close the productivity gap: accelerate open banking, real-time payments, and competition reforms flagged by the Bank of Canada.

- Tie incentives to uptime/throughput KPIs (not just capex), so public money buys performance, not promises.

- Scale talent retention: nurse-patient ratios, skilled-trades fast-track, and cross-border pay benchmarking, to curb outward flows.

- Credential recognition at industrial speed for engineers/techs, plus targeted workplace language training embedded on the shop floor.

🏭 What automakers & suppliers can do (operations playbook)

- Localize for tariff resilience and maintain Canadian best-cost operations with aggressive OEE, scrap, and changeover targets.

- Run a “first-time-through” war room for the next 12 months; tie supplier scorecards to ppm + responsiveness.

- Invest in shop-floor English + visual work instructions to lift safety and takt adherence in diverse teams.

- Adopt mixed-model EV/ICE flexibility where feasible to keep Canadian plants “always useful.”

- Lean + digital twins: simulate model switches before they hit the floor; verify with layered audits.

👷 What workers can do (practical next steps)

- Document your skills (APQP, metrology, robot programming, PLCs).

- Pursue micro-credentials (EV battery safety, high-voltage systems, ADAS calibration).

- Explore Windsor battery ecosystem and cross-training opportunities while the cell plant ramps.

- If impacted in Brampton, connect with union transition services and municipal job centers for retraining links to EV suppliers.

❓ FAQs

Q1. Is Stellantis leaving Canada entirely?

No. The company is adding a third shift in Windsor and continues building out the NextStar Energy EV battery JV. The change targets Jeep Compass assembly moving to Illinois.

Q2. Is this all because of Donald Trump?

Tariffs and political pressure are major factors, and leaders on both sides of the border acknowledge that. But productivity, costs, and localization strategy also matter.

Q3. Did Canada “pay” Stellantis to stay and get nothing?

Canada and Ontario offered large production incentives tied to output. Ottawa says moving Compass could breach commitments; legal options are on the table.

Q4. Is the U.S. poaching Canadian healthcare workers?

U.S. demand is strong and migration pathways are easy for nurses, but Ontario’s overall nursing supply is also growing. Retention (pay, ratios) is the issue.

Q5. Are wage subsidies paying firms to replace Canadians with immigrants?

No blanket program does that. Some subsidies support student hires or help integrate skilled newcomers; AFP has called out misinfo on “kickbacks.”

Q6. Why does productivity matter to car jobs?

Higher productivity lowers unit costs and attracts future nameplates. Canada’s recent declines make it harder to win internal investment fights.

🧭 Conclusion: Hard truths—and a path forward

Stellantis pulling investments out of Canada isn’t just about one model line. It’s a wake-up call on tariffs, productivity, and execution. We can’t control Washington, but we can control our cost, speed, and quality. That means faster policy action on productivity, smarter incentives tied to results, and real investment in people—Canadian-born and newcomer alike. Compete on output, safety, and first-time-through, and Canada wins its next nameplate.

📚 Sources & References

- Reuters coverage of the U.S. shift and tariff logic; AP & Global News political reactions; Guardian analysis of union response. (Reuters)

- Productivity & investment data: Statistics Canada, BLS, OECD, Bank of Canada. (Statistics Canada)

- Healthcare labour flows & supply: CGFNS, College of Nurses of Ontario. (cgfns.org)

- Wage subsidy program reality: Ontario Chamber TOP (students), WorkBC, ICTC newcomers, AFP fact-check. (OCC)

- Quality/recalls and rankings: Autoblog/Consumer data + J.D. Power IQS 2025. (Autoblog) jeep compass production

Bernard Aybout’s Lessons that matter – 20 years condensed (in plain language)

-

Localization pressure is real. Assume future models favor plants that are tariff-resilient and closest to the sales base.

Locate at the source!

-

Productivity wins budgets. Internal portfolio fights go to the plants with the best cost, speed, and first-time-through.

Product is allocated to plants on a competitive basis. Every plant must earn the right to build a future model.

-

Execution beats promises. Incentives and announcements mean little without PPAP/APQP discipline, supplier responsiveness, and line stability.

Ensure your suppliers understand the processes required to produce parts with consistent quality during an actual production run at production rates.

-

Talent is a constraint. Retention, cross-training, and shop-floor onboarding (including clear language/visual standards) directly show up in OEE and quality.

In practical terms, an employer must instruct its employees using both a language and vocabulary that the employees can understand.

-

Supplier ecosystems decide uptime. Dual sourcing, fast change control, and robust incoming quality are make-or-break.

Supply-chain disruptions cost the average organization 45% of one year’s profits over a decade.” (why supplier uptime/resilience matters)

The operations playbook

1) Throughput (quantity) — hit takt time, protect the bottleneck

-

Map flow end-to-end (value stream map); set takt and align each station’s cycle time.

-

Run a “Top 10 Losses” OEE war room (availability, performance, quality). Fix two losses per week.

-

SMED: standardize changeovers, pre-stage tools, quick-release fixturing; drive changeover to <10 minutes on high-mix lines.

-

Heijunka/mixed-model leveling to smooth demand and avoid feast/famine at constraints.

-

Andon + escalation within 60 seconds; team leader at the station within 2 minutes, engineering within 5.

-

TPM: autonomous maintenance checklists embedded in standard work; predictive for the true constraints.

2) Quality — “first-time-through” as the north star

-

Lock to IATF 16949 with living APQP/PPAP gates; refresh DFMEA/PFMEA after every engineering or supplier change.

-

Poka-Yoke at every critical characteristic; use torque/press-fit traceability and in-line vision for mistake-proofing.

-

SPC with real alarms (Western Electric rules) tied to line stops and containment.

-

Weekly layered process audits (LPA) by supervisors + managers; publish close-out rates.

-

8D on repeat defects; track PPM by part/supplier and link scorecards to sourcing decisions.

-

FTT ≥ 98% at the plant level; warranty and field returns are reviewed in the same room as daily scrap.

3) Cost & productivity — do more with the same headcount

-

Line balance and cell layout (U-shapes, optimal reach); kit high-mix parts, bulk low-mix.

-

Ergonomics & cobots on tedious, repeatable tasks to cut micro-stops and injuries.

-

Energy per unit dashboard (compressors, ovens, paint) with week-over-week reductions.

-

Design for Manufacturability (DFM/DFA): catch fasteners, tolerances, and service access before PPAP.

4) Workforce & culture — the multiplier

-

Skills matrix at team level; 2-deep coverage for every critical station.

-

Micro-credentials (battery safety, HV lockout, robot teach, metrology).

-

Visual standard work (icons, photos, short captions) and workplace language support where needed to reduce errors.

-

Daily tiered huddles (15 minutes): yesterday’s OEE/FTT, today’s risks, help needed.

-

Idea system: measure implemented ideas/employee/quarter; share savings on the floor.

5) Supplier resilience — uptime starts at the dock

-

Dual source (or at least dual-tooled) for A-risk parts; rehearse switchover.

-

Incoming quality by risk: 100% inspection on new/reworked lots until stability proven.

-

Change control: no silent revs—every engineering change re-runs PFMEA/control plan.

-

Supplier PPM + responsiveness on a public board; development visits for chronic offenders.

6) Digital & data — see problems in time to act

-

MES + IIoT: station-level cycle time, scrap reason codes, and downtime by block.

-

Live OEE, FTT, PPM, Changeover, TRIR, Energy/unit dashboards on the floor.

-

Digital Andon with root-cause tagging; monthly Pareto drives Kaizen pipeline.

-

Digital twins to simulate model mix and changeovers before you touch hardware.

7) Footprint & policy readiness — play the long game

-

Tariff/USMCA scenario plans: parts routing options, rules-of-origin compliance, domestic-content tracking.

-

Keep EV/ICE flexible capacity where feasible so the plant is always “useful” under shifting programs.

-

Tie internal capex approvals to measurable OEE/FTT gains, not just nameplate capacity.

Metrics that move the needle (use these targets)

-

OEE ≥ 85% on constraint assets

-

FTT ≥ 98% (plant), Station FTT ≥ 99.5% on critical ops

-

PPM < 25 at plant outgoing; 0 escapes on safety/critical features

-

Changeover < 10 min on high-mix lines

-

On-time delivery ≥ 98%; Schedule adherence ≥ 95%

-

Warranty: year-over-year defect rate ↓ ≥ 30% until best-in-class

-

TRIR < 1.0 and ergonomic risk scores trending down

-

Ideas implemented ≥ 2/employee/quarter

-

Energy per unit ↓ 10–15% YoY on major energy centers

30/60/90-day rollout (no drama, just execution)

Day 0–30 (Baseline & control)

-

Stand up the OEE/FTT war room; define loss taxonomy and daily cadence.

-

Lock station cycle times vs takt; map bottlenecks; freeze uncontrolled model changes.

-

Start LPAs and Andon escalation; publish first supplier scorecard.

Day 31–60 (Pilot & prove)

-

SMED pilot on one constraint; show a 40–60% changeover cut.

-

Install poka-yoke on two top defect modes; drive FTT +2 points.

-

Launch skills matrix + cross-training in the bottleneck area.

-

Turn on live dashboards at cell and team levels.

Day 61–90 (Scale & lock)

-

Scale SMED to the next two assets; extend LPAs plant-wide.

-

Supplier development on the top three PPM offenders; temporary 200% incoming checks.

-

Tie supervisor bonuses to OEE, FTT, and implemented ideas, not just output.

-

Approve capex with pre/post KPI commitments (no KPI, no spend).

🙂 Employee morale & retention — the hidden OEE lever

When people feel respected, trained, and heard, you get steadier takt adherence, fewer short-stops, and cleaner first-time-through. Make morale visible, improve it deliberately, and tie it to output.

Do now (playbook)

-

Rituals: 15-min tier huddles with one daily shout-out; no-blame Andon (support at the station in minutes).

-

Voice & recognition: Simple idea system (submit→triage in 48h→implement or explain); publish ideas implemented/employee/quarter and share savings.

-

Growth: Skills matrix with 2-deep coverage, micro-credentials (HV safety, metrology, robot teach), and skill-based pay ladders that show how to earn more.

-

Fairness & predictability: Rotations to reduce fatigue; cap forced OT; 48-hour notice for schedule changes; easy shift-swap board.

-

Ergonomics & safety: Fix top 5 pain points (reach, lift, torque), rotate jobs, use cobots on tedious tasks, and track TRIR alongside OEE.

-

Onboarding & clarity: Visual standard work (photos/icons), shop-floor language support where needed, and buddy onboarding for the first 30 shifts.

Measure it (leading + lagging)

-

Leading: eNPS/pulse (3–5 questions monthly), ideas implemented/employee/quarter, training hours/employee, Andon response SLA met %, LPA completion %.

-

Lagging: Voluntary turnover %, absenteeism %, TRIR, FTT %, OEE on constraint, warranty/PPM trend.

-

Target examples: ≥2 implemented ideas/employee/quarter, Andon SLA ≥95%, eNPS trending up 5+ points/quarter, TRIR <1.0.

30/60/90 morale rollout

-

0–30: Launch monthly pulse survey; publish skills matrix; fix the top 3 everyday annoyances; start daily shout-outs.

-

31–60: Turn on idea system with 48h triage SLA; pilot skill-based pay in one area; standardize schedule-predictability rules.

-

61–90: Train team leads on coaching/feedback; expand cobot/ergonomic fixes; post a “people + performance” board (eNPS, ideas, OEE, FTT) at the gemba.

Quick checklists you can copy

FTT Boost (weekly)

-

Top 3 defects → 8D owner assigned

-

Poka-yoke added or verified effective

-

SPC limits reviewed; alarms verified

-

Work instructions updated with photos/video

-

Containment removed only after stability

Throughput Boost (daily)

-

Constraint running? If not, why not (coded reason)

-

Changeover time logged and compared to target

-

Pre-staged tools/parts ready for next mix

-

Andon activations closed within SLA

-

Maintenance PMs at 100% completion

People & Safety

-

Skills matrix updated; no single-point failures

-

Ergonomic red flags actioned

-

15-minute tiered huddles completed

-

5S audits green; parts presentation verified