Approx. read time: 101 min.

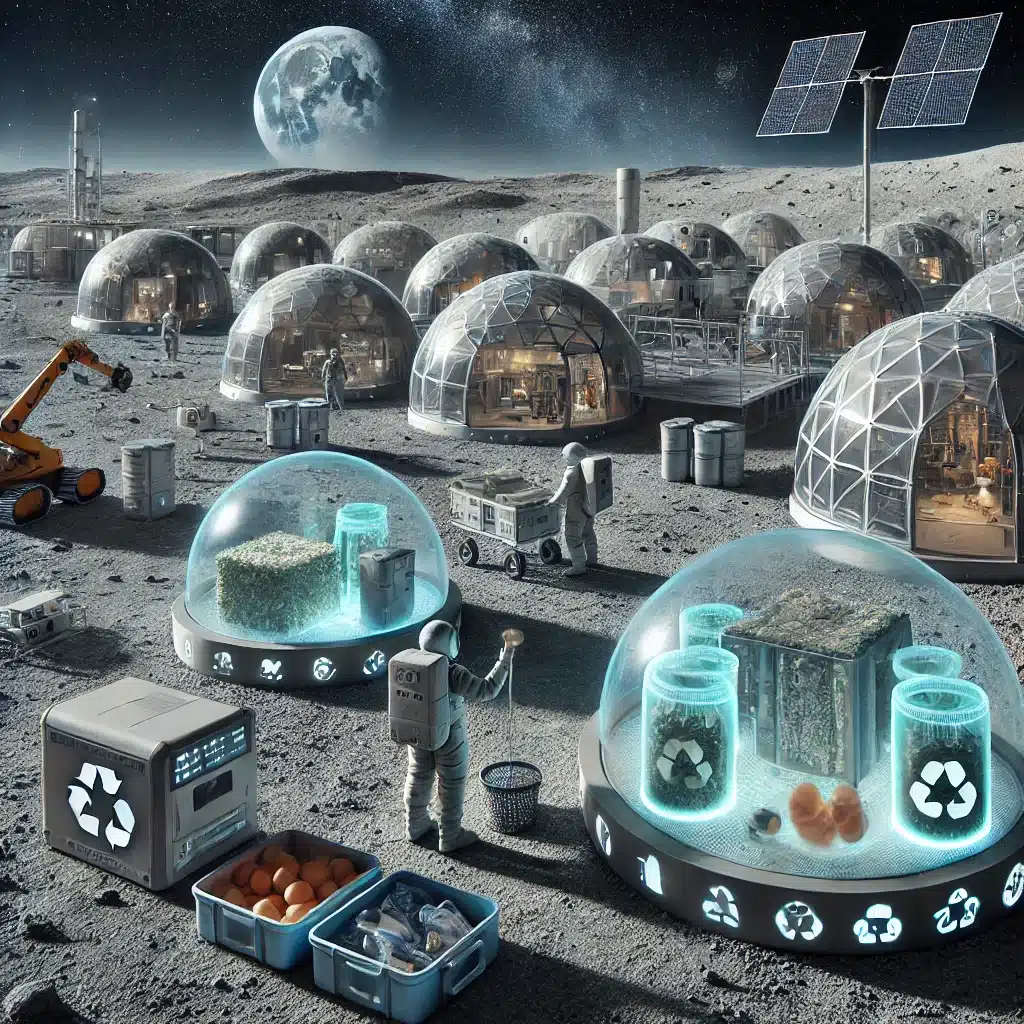

Post: Innovative Waste Management Strategies for Sustainable Long-Term Lunar Missions: Addressing Challenges of Low Gravity, Extreme Temperatures, and High Radiation

Introduction – lunar waste management systems

Long-term lunar missions require sustainable waste management systems that are resilient to the Moon’s harsh conditions. By accounting for low gravity, extreme temperatures, and high radiation levels, we can develop innovative solutions for processing waste materials like old clothing and food packaging. These solutions not only aim to minimize waste but also to repurpose it, contributing to a closed-loop life support system essential for lunar habitation.

1. Recycling and Repurposing Materials

Material Recovery Facilities (MRFs)

Consideration of Lunar Environment:

- Low Gravity: MRF equipment must function efficiently in low gravity. This requires redesigning machinery to handle material movement and sorting without relying on Earth’s gravity. Conveyors, for example, may need to use mechanical grips or air suction systems.

- Extreme Temperatures: Equipment must be insulated and possibly housed within temperature-controlled environments to prevent malfunction due to temperature-induced material expansion or contraction.

- High Radiation Levels: Electronic components should be shielded against radiation to prevent damage. Materials used in constructing MRFs should be selected for their radiation resistance.

Implementation:

- Sealed Environments: MRFs should operate within pressurized modules to protect against vacuum conditions and to contain fine particulate matter that could be hazardous if released.

- Robust Materials: Use materials that can withstand lunar dust abrasion, which can cause significant wear due to its sharp, jagged particles.

- Energy Efficiency: Systems should be designed to minimize energy consumption, given the limited energy resources on the Moon.

3D Printing with Recycled Materials

Consideration of Lunar Environment:

- Low Gravity: 3D printers must be adapted to prevent material from floating away. This could involve using adhesive print beds or enclosing the printing area to contain materials.

- Temperature Fluctuations: Printers and stored materials need thermal regulation to maintain optimal operating temperatures and prevent material brittleness or deformation.

- Radiation: Printers and recycled material stock must be shielded to prevent degradation from radiation, which can alter the properties of plastics and polymers.

Implementation:

- Enclosed Printing Chambers: Maintain controlled environments within the printer to manage temperature and contain materials.

- Material Stabilization: Additives might be needed to stabilize recycled materials against radiation-induced degradation.

- Quality Control: Implement monitoring systems to ensure printed items meet required specifications despite environmental challenges.

Fiber Reprocessing

Consideration of Lunar Environment:

- Low Gravity: Fiber processing equipment must be designed to handle materials without relying on gravity-fed systems. This may involve mechanical feeders and collectors.

- Temperature Control: Reprocessing facilities need to maintain stable temperatures to ensure fibers do not become too brittle or too soft, affecting the quality of the processed material.

- Radiation Exposure: Textiles and fibers can degrade under radiation. Shielding and protective coatings may be necessary during storage and processing.

Implementation:

- Mechanical Adaptations: Use suction or mechanical arms to move fibers through processing stages.

- Thermal Insulation: Facilities should be insulated to maintain consistent temperatures for machinery and materials.

- Radiation-Resistant Materials: Incorporate materials that resist radiation for both equipment and processed fibers.

2. Organic Waste Processing – lunar waste management systems

Bioreactors

Consideration of Lunar Environment:

- Low Gravity: Microorganisms in bioreactors may behave differently in low gravity. Fluid dynamics change, affecting nutrient and gas exchange.

- Temperature Fluctuations: Bioreactors require precise temperature control for optimal microbial activity.

- Radiation: High radiation levels can harm microorganisms. Bioreactors must be shielded to protect the microbial cultures.

Implementation:

- Microgravity-Compatible Designs: Use bioreactors that promote mixing and gas exchange without relying on gravity, such as rotating wall vessel bioreactors.

- Thermal Control Systems: Equip bioreactors with heating and cooling systems to maintain ideal temperatures.

- Radiation Shielding: Place bioreactors in shielded areas, possibly underground or within the habitat’s protective structures.

Composting Systems

Consideration of Lunar Environment:

- Low Gravity: Composting relies on microbial action, which may be affected by low gravity. The movement of gases and liquids within the compost pile differs from Earth.

- Temperature Control: Composting generates heat, but external temperature extremes could impact the process.

- Radiation: Radiation can sterilize microorganisms, halting the composting process.

Implementation:

- Enclosed Composting Units: Design units that contain and control the composting environment, possibly using rotating drums to facilitate mixing.

- Insulation and Heating: Include insulation to retain heat generated by composting and add heating elements if necessary to maintain microbial activity during lunar night.

- Radiation Protection: Situate composting systems within shielded areas to protect microbes.

3. Thermal and Chemical Processing

Pyrolysis and Gasification

Consideration of Lunar Environment:

- Low Gravity: Material feed systems must be designed to ensure consistent input into reactors without gravity assistance.

- Extreme Temperatures: Thermal processes generate high heat, so equipment must withstand internal temperatures while being insulated from external cold.

- Radiation: Reactor materials must resist radiation-induced degradation.

Implementation:

- Sealed Systems: Use pressurized and sealed reactors to contain gases and prevent leaks in the vacuum of space.

- Thermal Insulation: Employ multi-layer insulation to maintain internal temperatures and protect the surrounding habitat.

- Robust Materials: Construct reactors from materials like ceramics or metals that withstand both high temperatures and radiation.

Depolymerization

Consideration of Lunar Environment:

- Low Gravity: Chemical reaction vessels need to ensure proper mixing and contact between reactants in low gravity.

- Temperature Control: Reactions may be endothermic or exothermic, requiring precise thermal management.

- Radiation: Chemicals and catalysts must be stored and handled in ways that prevent radiation-induced degradation or unintended reactions.

Implementation:

- Stirring Mechanisms: Use mechanical or magnetic stirrers adapted for low gravity to maintain homogeneity in reaction mixtures.

- Thermal Management Systems: Equip reactors with heating/cooling jackets to regulate reaction temperatures.

- Shielded Storage: Store chemicals in radiation-proof containers.

4. Design for Sustainability

Multipurpose Packaging

Consideration of Lunar Environment:

- Low Gravity: Packaging must remain functional in low gravity, both during initial use and when repurposed.

- Temperature Extremes: Materials should maintain integrity despite temperature fluctuations.

- Radiation: Packaging materials need to resist radiation to be effective when repurposed for construction or shielding.

Implementation:

- Durable Materials: Use materials like polyethylene, which is effective for radiation shielding and remains stable across temperature ranges.

- Modular Design: Create packaging that can interlock or connect when repurposed, facilitating assembly in low gravity.

- Material Stability: Ensure materials do not become brittle or degrade under radiation exposure.

Edible Packaging

Consideration of Lunar Environment:

- Low Gravity: Edible packaging must stay attached to food items and not float away, preventing contamination and waste.

- Temperature Control: Ensure the packaging remains palatable and safe across temperature fluctuations.

- Radiation Exposure: Edible materials need to be protected from radiation to remain safe for consumption.

Implementation:

- Adhesive Properties: Design packaging that adheres well to food surfaces in low gravity.

- Storage Solutions: Keep food items in shielded, temperature-controlled compartments.

- Protective Packaging: Use outer protective layers that can be removed before consumption to protect the edible packaging.

Modular Clothing Systems

Consideration of Lunar Environment:

- Low Gravity: Clothing must be designed to stay in place without the full effect of gravity, possibly incorporating adjustable fittings.

- Temperature Extremes: Materials should provide insulation against the cold and breathability for warmth during lunar day.

- Radiation Protection: Clothing may need to incorporate radiation-shielding materials, especially during extravehicular activities (EVAs).

Implementation:

- Adjustable Fittings: Use elastic materials and adjustable straps or fastenings.

- Layered Clothing: Design clothing systems with removable layers for temperature regulation.

- Radiation-Resistant Fabrics: Incorporate fabrics with embedded radiation-shielding properties, such as those containing polyethylene fibers.

5. In-Situ Resource Utilization (ISRU)

Regolith Integration

Consideration of Lunar Environment:

- Low Gravity: Mixing waste materials with regolith requires equipment that can blend materials effectively without gravity-assisted settling.

- Temperature Extremes: Materials and composites must withstand thermal cycling without cracking or degrading.

- Radiation Exposure: Incorporating waste into regolith composites can enhance radiation shielding properties.

Implementation:

- Mechanical Mixers: Use enclosed mixing systems that can operate in low gravity, possibly using counter-rotating drums.

- Thermal Cycling Tests: Test composite materials for durability under simulated lunar day-night cycles.

- Radiation Shielding Optimization: Analyze composite materials for their effectiveness in attenuating radiation.

Radiation Shielding

Consideration of Lunar Environment:

- High Radiation Levels: Utilizing waste materials in shielding directly addresses the radiation challenge on the Moon.

- Material Stability: Waste materials must remain stable under radiation exposure to maintain shielding effectiveness.

- Temperature Fluctuations: Shielding materials should not degrade or change properties with temperature changes.

Implementation:

- Layered Shielding Design: Combine waste materials with regolith or other shielding substances to enhance protection.

- Material Testing: Assess long-term stability of waste-based shielding under radiation and thermal cycling.

- Structural Integration: Ensure that incorporating waste into shielding does not compromise structural integrity.

6. Advanced Waste Management Technologies

Plasma Gasification

Consideration of Lunar Environment:

- Low Gravity: Feeding waste into the plasma reactor requires mechanisms to ensure consistent input flow.

- Vacuum Conditions: Plasma systems must be sealed to operate correctly and prevent plasma from interacting with the lunar vacuum.

- Temperature Control: High-temperature operations need robust thermal insulation to protect the habitat.

Implementation:

- Pressurized Chambers: House plasma reactors within pressurized environments to maintain operational conditions.

- Material Handling Systems: Develop waste feed systems that can transport materials in low gravity without blockages.

- Thermal Shielding: Incorporate advanced insulation materials to contain heat within the reactor.

Electrochemical Systems

Consideration of Lunar Environment:

- Low Gravity: Electrochemical processes may be affected by altered fluid dynamics, requiring specialized cell designs.

- Temperature Regulation: Electrochemical reactions often require specific temperature ranges.

- Radiation: Protect sensitive components from radiation-induced degradation.

Implementation:

- Microgravity-Compatible Cells: Design cells with capillary action or microfluidic channels to move liquids effectively.

- Thermal Management: Include heating elements or insulation to maintain optimal reaction temperatures.

- Radiation Shielding: Use radiation-resistant materials for cell construction and shielding for sensitive electronics.

7. Biotechnological Solutions

Synthetic Biology

Consideration of Lunar Environment:

- Low Gravity: Microbial growth and metabolism may be altered in low gravity; organisms may require genetic modifications to function properly.

- Radiation: High radiation levels can damage DNA, necessitating radiation-resistant strains.

- Temperature Extremes: Microbes need stable temperatures; bioreactors must insulate and regulate internal temperatures.

Implementation:

- Radiation-Resistant Organisms: Engineer microbes with enhanced DNA repair mechanisms or protective pigments.

- Controlled Environments: Use bioreactors with precise environmental controls to simulate Earth-like conditions.

- Microgravity Studies: Prior to deployment, conduct experiments to understand microbial behavior in low gravity.

Algae Cultivation

Consideration of Lunar Environment:

- Low Gravity: Fluid handling and gas exchange in photobioreactors are affected, requiring innovative designs.

- Temperature and Light: Algae require specific light and temperature conditions, necessitating artificial lighting and thermal control.

- Radiation Protection: Algae cells are sensitive to radiation; reactors need shielding.

Implementation:

- Photobioreactor Design: Utilize airlift or bubble column reactors adapted for low gravity to ensure proper mixing and gas exchange.

- LED Lighting Systems: Provide artificial light spectra optimized for photosynthesis.

- Radiation Shielding: Incorporate transparent shielding materials like polyethylene for reactors.

8. Waste-to-Energy Conversion

Microbial Fuel Cells

Consideration of Lunar Environment:

- Low Gravity: Electron transfer and ion movement in microbial fuel cells may be impacted; design adjustments are necessary.

- Temperature Control: Microbial activity is temperature-dependent; systems need thermal regulation.

- Radiation: Microbes must be shielded from radiation to maintain functionality.

Implementation:

- Electrode Design: Optimize electrodes to function efficiently in low gravity, possibly using 3D structures to increase surface area.

- Thermal Insulation: Include heating elements to maintain temperatures conducive to microbial metabolism.

- Protective Enclosures: Shield the entire system to protect against radiation.

Thermoelectric Generators

Consideration of Lunar Environment:

- Temperature Extremes: The Moon’s natural temperature differences can be harnessed, but materials must withstand thermal stress.

- Material Selection: Thermoelectric materials must perform efficiently across wide temperature ranges and resist radiation.

Implementation:

- Utilizing Thermal Gradients: Position thermoelectric generators between warm waste processing units and the cold lunar environment to maximize efficiency.

- Durable Materials: Use thermoelectric materials like skutterudites, which are efficient and stable under extreme conditions.

- Radiation Hardening: Select materials that maintain thermoelectric properties despite radiation exposure.

9. Automation and Robotics

Autonomous Waste Sorting Robots

Consideration of Lunar Environment:

- Low Gravity: Robots must have traction and mobility systems adapted for low gravity to prevent slipping or floating.

- Temperature Fluctuations: Robotic systems require thermal management to prevent overheating or freezing of components.

- Radiation: Electronics and sensors must be shielded from radiation to prevent malfunctions.

Implementation:

- Mobility Solutions: Use magnetic wheels or anchoring systems to maintain contact with surfaces.

- Thermal Control: Incorporate heating elements and insulation within the robot’s body.

- Radiation-Hardened Electronics: Utilize components designed to resist radiation damage.

Robotic Fabrication

Consideration of Lunar Environment:

- Low Gravity: Fabrication processes must prevent materials from floating away, requiring containment systems.

- Temperature Stability: Manufacturing equipment must operate consistently despite external temperature changes.

- Radiation Exposure: Protect robotic systems and processed materials from radiation.

Implementation:

- Enclosed Workspaces: Use sealed chambers where robots manipulate materials in a controlled environment.

- Adaptive Tools: Equip robots with tools designed for precise manipulation in low gravity.

- Material Handling: Implement methods to secure materials, such as electrostatic plates or vacuum grips.

10. Policy and Collaboration

International Standards

Consideration of Lunar Environment:

- Uniform Safety Protocols: Standards must account for environmental challenges to ensure safety across international missions.

- Material Compatibility: Agree on materials and systems that perform reliably under lunar conditions.

Implementation:

- Collaborative Research: Conduct joint studies to understand how different technologies perform on the Moon.

- Standard Development: Create guidelines that incorporate environmental considerations like radiation shielding requirements.

Open Innovation Platforms

Consideration of Lunar Environment:

- Knowledge Sharing: Sharing data on environmental effects can accelerate innovation in designing lunar-adapted systems.

Implementation:

- Data Repositories: Establish databases containing information on material performance under lunar conditions.

- Collaborative Tools: Use virtual reality simulations to model environmental impacts on proposed solutions.

11. Solar Thermal Processing

Concept:

Utilize the abundant solar energy on the Moon by implementing solar thermal systems to process waste materials, including old clothing and food packaging.

Implementation:

- Solar Concentrators: Use mirrors or lenses to focus sunlight to generate high temperatures needed for processing waste.

- Thermal Decomposition: High temperatures can break down organic materials into simpler compounds or sterilize waste for safe handling.

- Melting and Reforming Plastics: Concentrated solar heat can melt plastic waste, allowing it to be remolded into new products or materials.

Consideration of Lunar Environment:

- Extreme Temperature Fluctuations: The system must be insulated to retain heat during the lunar night and prevent overheating during the lunar day.

- Low Gravity: Equipment must be designed to function efficiently without relying on gravity-assisted processes.

- High Radiation Levels: Materials used in solar concentrators should be resistant to degradation from intense solar and cosmic radiation.

Benefits:

- Energy Efficiency: Reduces reliance on electrical power by harnessing solar energy.

- Resource Utilization: Enables recycling and repurposing of waste materials on-site.

- Scalability: Systems can be scaled based on the volume of waste generated.

Challenges:

- Day-Night Cycle: The lunar day lasts about 14 Earth days, followed by 14 days of night, requiring thermal storage solutions or alternative processing methods during the night.

- Material Durability: Components must withstand harsh environmental conditions over long periods.

12. Vacuum Pyrolysis

Concept:

Leverage the Moon’s natural vacuum environment to perform pyrolysis of waste materials without the need for atmospheric control.

Implementation:

- Vacuum Chambers: Place waste materials in containers exposed to the lunar vacuum, where reduced pressure facilitates pyrolysis at lower temperatures.

- Heat Sources: Use solar or nuclear-powered heaters to provide the necessary thermal energy.

- Byproduct Collection: Capture gases and vapors released during pyrolysis for potential use as fuel or in life support systems.

Consideration of Lunar Environment:

- Vacuum Conditions: The natural vacuum aids in reducing the boiling points of substances, making pyrolysis more energy-efficient.

- Temperature Control: Systems must protect against external temperature extremes to maintain consistent processing conditions.

- Radiation: Equipment should shield sensitive components from radiation to prevent degradation.

Benefits:

- Energy Efficiency: Reduced pressure lowers the energy required for pyrolysis.

- Resource Recovery: Converts waste into useful byproducts like oils, gases, and char.

- Environmental Compatibility: Minimizes the risk of atmospheric contamination within the habitat.

Challenges:

- Thermal Management: Ensuring even heating in the vacuum to prevent cold spots and incomplete pyrolysis.

- Material Handling: Developing methods to load and unload waste materials in the vacuum without exposing the habitat to the external environment.

13. Regolith-Based Biocomposite Production

Concept:

Combine organic waste with lunar regolith to create biocomposite materials for construction or manufacturing.

Implementation:

- Binding Agents: Develop or bring bio-based binders that can mix with shredded waste and regolith.

- Compression Molding: Use presses to form composite materials into desired shapes and sizes.

- Curing Processes: Employ solar heat or microwave sintering to harden the composites.

Consideration of Lunar Environment:

- Low Gravity: Equipment must apply sufficient force for compression molding without gravity’s assistance.

- Temperature Extremes: Curing processes need to be insulated from external temperatures to ensure material integrity.

- Radiation: Finished biocomposites should withstand radiation exposure without degrading.

Benefits:

- Material Innovation: Creates new materials with potentially advantageous properties for lunar infrastructure.

- Waste Reduction: Utilizes waste that would otherwise require storage or disposal.

- In-Situ Resource Utilization (ISRU): Reduces the amount of material that must be transported from Earth.

Challenges:

- Material Properties: Ensuring the mechanical strength and durability of biocomposites in the lunar environment.

- Process Development: Requires research into suitable binders and processing techniques compatible with lunar conditions.

14. Electrochemical Waste Oxidation

Concept:

Use electrochemical cells to oxidize organic waste materials, converting them into carbon dioxide, water, and other simpler molecules.

Implementation:

- Electrochemical Reactors: Design reactors that can process solid and liquid waste streams.

- Catalysts: Utilize robust catalysts that function effectively under lunar conditions.

- Integration with Life Support: Feed the resulting carbon dioxide and water into life support systems for reuse.

Consideration of Lunar Environment:

- Low Gravity: Reactor designs must ensure effective contact between waste, catalysts, and electrodes without gravity-driven mixing.

- Temperature Control: Maintain optimal operating temperatures despite external fluctuations.

- Radiation Protection: Shield reactors to prevent damage to catalysts and membranes.

Benefits:

- Efficient Waste Reduction: Quickly reduces the volume of waste.

- Resource Recovery: Generates water and carbon dioxide for life support systems.

- Energy Generation: Potential to produce electrical energy as a byproduct.

Challenges:

- Energy Requirements: May require significant electrical power to operate.

- System Complexity: Advanced technology that requires maintenance and expertise.

15. High-Efficiency Incineration with Emission Capture

Concept:

Implement high-temperature incineration systems with complete emission capture to safely burn waste materials.

Implementation:

- Closed Combustion Chambers: Design sealed incinerators that prevent the release of harmful gases into the habitat.

- Emission Scrubbers: Install filtration systems to clean combustion gases, capturing pollutants and recovering usable gases.

- Energy Recovery: Use the heat generated for other processes or convert it into electricity using thermoelectric generators.

Consideration of Lunar Environment:

- Oxygen Supply: Requires careful management of oxygen resources to support combustion.

- Thermal Insulation: Insulate incinerators to protect the habitat and equipment from extreme heat.

- Radiation Shielding: Protect electronic controls and sensors from radiation damage.

Benefits:

- Volume Reduction: Significantly reduces the volume of waste needing storage.

- Resource Recovery: Captured emissions can be processed for useful components.

- Energy Utilization: Heat can be repurposed, improving overall energy efficiency.

Challenges:

- Oxygen Consumption: Must balance oxygen use with life support needs.

- Safety Risks: High-temperature operations require robust safety protocols to prevent accidents.

16. Freeze-Drying of Organic Waste

Concept:

Use the Moon’s cold temperatures, especially during the lunar night, to freeze-dry organic waste, reducing its volume and preserving it for future processing.

Implementation:

- Exposure Chambers: Place waste in insulated containers that can be exposed to the cold vacuum to sublimate moisture.

- Moisture Capture: Collect water vapor released during freeze-drying for reuse.

- Storage Solutions: Store dehydrated waste safely until it can be further processed or utilized.

Consideration of Lunar Environment:

- Temperature Extremes: Harness the natural cold during the lunar night effectively.

- Vacuum Conditions: Leverage the vacuum to facilitate sublimation without additional energy input.

- Radiation: Shield stored waste to prevent degradation or contamination.

Benefits:

- Energy Efficiency: Minimal energy required compared to mechanical drying methods.

- Water Recovery: Reclaims water from waste for reuse in the habitat.

- Waste Stabilization: Reduces biological activity, preventing odor and pathogen growth.

Challenges:

- Timing: Process is dependent on the lunar day-night cycle.

- Equipment Durability: Systems must withstand repeated thermal cycling.

17. Electrodynamic Dust Shielding for Waste Containment

Concept:

Use electrodynamic dust shield technology to control and contain fine waste particles, preventing contamination of the habitat and equipment.

Implementation:

- Electrodynamic Screens: Install around waste processing areas to repel dust and small particles using electric fields.

- Particle Manipulation: Use controlled electric or magnetic fields to move or sort waste particles.

- Integration with Systems: Combine with air filtration and ventilation to maintain a clean environment.

Consideration of Lunar Environment:

- Low Gravity: Fine particles can remain suspended longer, increasing the risk of inhalation or equipment contamination.

- Radiation: Electronic components must be shielded to prevent malfunction due to radiation exposure.

- Vacuum Conditions: Systems must operate effectively within pressurized habitats.

Benefits:

- Environmental Control: Enhances cleanliness and reduces health risks.

- Equipment Protection: Prolongs the lifespan of machinery by preventing dust ingress.

- Efficiency: Improves the effectiveness of waste processing by controlling particle dispersion.

Challenges:

- Power Consumption: Requires continuous energy input to maintain fields.

- Complexity: Adds another layer of technology to manage and maintain.

18. Use of Bacteria and Enzymes for Material Degradation

Concept:

Employ specially engineered bacteria or enzymes capable of breaking down synthetic polymers found in clothing and packaging.

Implementation:

- Microbial Cultivation: Grow microorganisms in bioreactors designed for low-gravity conditions.

- Enzyme Extraction: Harvest enzymes that can function outside of living cells for added safety and control.

- Safety Measures: Implement strict biocontainment to prevent unintended spread.

Consideration of Lunar Environment:

- Radiation Protection: Microbes and enzymes must be shielded from radiation to maintain functionality.

- Temperature Control: Maintain optimal temperatures for biological activity.

- Low Gravity Effects: Study and mitigate any impacts on microbial metabolism and enzyme activity.

Benefits:

- Targeted Degradation: Efficiently breaks down specific waste materials that are otherwise difficult to recycle.

- Resource Recovery: Converts waste into simpler compounds that can be repurposed.

- Sustainability: Reduces reliance on physical or chemical methods that may be more resource-intensive.

Challenges:

- Biosecurity: Risk of contamination or unintended ecological impacts within the habitat.

- Efficiency: Biological processes may be slower than mechanical or chemical methods.

19. Zero-Waste Design Principles

Concept:

Adopt a zero-waste philosophy in the design of mission equipment, packaging, and consumables to minimize waste generation from the outset.

Implementation:

- Design for Disassembly: Create products that are easy to take apart for recycling or repurposing.

- Standardization: Use uniform materials and components to simplify recycling processes.

- Multi-Functionality: Design items to serve multiple purposes throughout their lifecycle.

Consideration of Lunar Environment:

- Material Performance: Ensure that sustainable materials meet the stringent requirements of the lunar environment.

- Durability: Products must withstand radiation, temperature extremes, and mechanical stresses.

- Low Gravity: Design items to function effectively in low gravity, possibly reducing the need for certain materials.

Benefits:

- Waste Reduction: Minimizes the amount of waste needing processing.

- Resource Efficiency: Makes better use of limited materials brought from Earth.

- Simplifies Logistics: Streamlines inventory and reduces mission complexity.

Challenges:

- Initial Costs: May require more investment in research and development.

- Performance Trade-offs: Sustainable materials may not always match the performance of traditional options.

20. Psychological and Social Approaches to Waste Minimization

Concept:

Address waste generation through crew training, awareness, and behavioral strategies that encourage conservation and efficient use of resources.

Implementation:

- Education Programs: Train crew members on the importance of waste management and resource conservation.

- Feedback Systems: Provide real-time data on waste generation to promote mindful consumption.

- Incentive Structures: Implement rewards or recognition for achieving waste reduction goals.

Consideration of Lunar Environment:

- Isolation and Stress: Acknowledge that psychological factors can impact behavior; provide support to maintain high morale and cooperation.

- Cultural Differences: If international crews are involved, consider cultural attitudes towards waste and conservation.

Benefits:

- Immediate Impact: Behavioral changes can quickly reduce waste generation.

- Cost-Effective: Requires minimal additional resources to implement.

- Team Cohesion: Promotes a culture of responsibility and teamwork.

Challenges:

- Consistency: Sustaining behavioral changes over long missions.

- Measurement: Quantifying the impact of psychological strategies on waste reduction.

21. Supercritical Water Oxidation

Concept:

Utilize supercritical water oxidation (SCWO) to process organic waste materials, converting them into carbon dioxide, water, and inert salts.

Implementation:

- SCWO Reactors: Design compact reactors capable of operating under the high pressures and temperatures required to bring water to a supercritical state (above 374°C and 22 MPa).

- Waste Input: Feed organic waste, including food packaging and textile fibers, into the reactor mixed with water.

- Reaction Process: In the supercritical state, water becomes a powerful solvent for organic compounds, facilitating rapid oxidation without the need for catalysts.

Consideration of Lunar Environment:

- Low Gravity: Reactor design must ensure proper mixing and flow of reactants without gravity-assisted convection. Pumps and mixers must function efficiently in low gravity.

- Temperature Control: Extreme external temperatures necessitate robust insulation and thermal regulation within the reactor to maintain supercritical conditions.

- High Radiation Levels: Reactor materials and electronic controls must be shielded against radiation to prevent degradation and ensure safety.

Benefits:

- Complete Destruction of Organic Waste: SCWO can achieve near-total oxidation of organic compounds, significantly reducing waste volume.

- Resource Recovery: Produces water and carbon dioxide that can be recycled into life support systems.

- Minimal Residuals: Generates small amounts of inert salts, reducing the need for waste storage.

Challenges:

- High Energy Requirements: The process requires substantial energy input to maintain supercritical conditions, necessitating efficient energy sources.

- Complex Equipment: High-pressure and high-temperature systems increase the complexity and potential maintenance needs.

22. Photocatalytic Degradation Using Lunar Regolith

Concept:

Employ photocatalysts derived from lunar regolith minerals to break down organic waste under ultraviolet (UV) light exposure.

Implementation:

- Photocatalyst Development: Extract and process titanium dioxide (TiO₂) or other photocatalytic minerals from lunar soil.

- Waste Treatment Chambers: Design chambers where waste materials are coated with the photocatalyst and exposed to concentrated UV light, potentially using the Moon’s unfiltered solar radiation.

- Reaction Process: UV light activates the photocatalyst, generating reactive oxygen species that decompose organic compounds in the waste.

Consideration of Lunar Environment:

- Abundant UV Radiation: The Moon’s lack of atmosphere allows for high levels of solar UV radiation, which can be harnessed for photocatalysis.

- Temperature Fluctuations: Systems must protect against extreme temperatures that could affect photocatalyst stability and reaction rates.

- Low Gravity: Waste handling and catalyst application methods must function effectively without gravity-dependent processes.

Benefits:

- Utilizes In-Situ Resources: Reduces the need to bring photocatalysts from Earth by using lunar materials.

- Energy Efficiency: Leverages solar energy, minimizing additional power requirements.

- Reduces Chemical Use: Avoids the need for added chemicals or reagents.

Challenges:

- Exposure Risks: UV radiation is harmful to humans; systems must ensure crew safety by containing UV exposure.

- Efficiency: The effectiveness of photocatalytic degradation on various waste types needs thorough testing.

23. Microencapsulation of Hazardous Waste

Concept:

Encapsulate hazardous or non-recyclable waste in durable, radiation-resistant materials to prevent environmental contamination and allow for safe storage or repurposing.

Implementation:

- Encapsulation Materials: Develop or utilize materials such as lunar glass or ceramics produced from regolith that can encapsulate waste securely.

- Process: Embed waste materials within the encapsulating medium through melting or sintering processes.

- Storage or Utilization: Store encapsulated waste safely or use it as filler material in construction, such as in radiation shielding blocks.

Consideration of Lunar Environment:

- Low Gravity: Processes must ensure complete encapsulation without voids, which may be challenging without gravity to assist material settling.

- Temperature Extremes: Encapsulation materials must withstand thermal cycling without cracking or releasing encapsulated waste.

- Radiation: Encapsulation materials should be radiation-resistant to maintain integrity over time.

Benefits:

- Environmental Protection: Prevents the release of hazardous substances into the lunar habitat.

- Resource Utilization: Encapsulated waste can serve a secondary purpose in construction.

- Safety: Reduces the risk of crew exposure to hazardous materials.

Challenges:

- Energy Consumption: High temperatures required for melting or sintering demand significant energy input.

- Material Compatibility: Ensuring encapsulation materials bond effectively with different waste types.

24. High-Pressure Waste Compaction

Concept:

Compress waste materials into dense, solid blocks using high-pressure compaction, reducing volume and potentially creating usable construction materials.

Implementation:

- Compaction Equipment: Design presses capable of exerting high pressures in low-gravity conditions, possibly using mechanical advantage or hydraulic systems adapted for the lunar environment.

- Waste Processing: Sort and prepare waste to ensure compatibility and safety before compaction.

- Product Utilization: Use compacted blocks as structural elements, shielding materials, or for other construction purposes within the lunar base.

Consideration of Lunar Environment:

- Low Gravity: Equipment must anchor securely to the lunar surface or habitat structures to counteract reaction forces during compaction.

- Temperature Fluctuations: Machinery must operate reliably across temperature extremes, requiring insulation and temperature regulation.

- Radiation Exposure: Compacted waste blocks can contribute to radiation shielding if designed appropriately.

Benefits:

- Volume Reduction: Significantly decreases the space needed for waste storage.

- Material Reuse: Transforms waste into practical building materials.

- Simplicity: Mechanical compaction is a straightforward process with relatively low technological complexity.

Challenges:

- Equipment Mass and Size: Compaction equipment may be heavy and bulky, impacting transport and installation logistics.

- Material Properties: Not all waste materials may bond well under compaction, affecting the structural integrity of the blocks.

25. Microwave Waste Treatment

Concept:

Use microwave energy to heat and sterilize waste materials, reducing volume and preparing them for safe disposal or reuse.

Implementation:

- Microwave Reactors: Install microwave systems designed to operate safely within the lunar habitat, with shielding to contain radiation.

- Waste Processing: Load waste into the reactor where microwaves induce thermal and non-thermal effects, breaking down organic matter and sterilizing biological contaminants.

- Byproduct Handling: Collect gases and residues produced during the process for potential reuse or safe disposal.

Consideration of Lunar Environment:

- Low Gravity: Reactor designs must ensure even heating and prevent hot spots without relying on gravity for material settling.

- Thermal Management: Excess heat must be dissipated to prevent overheating of the habitat, possibly using heat exchangers linked to external radiators.

- Radiation Safety: Microwaves must be contained within the reactor to protect crew members and sensitive equipment.

Benefits:

- Sterilization: Effectively kills pathogens, making waste safer to handle.

- Volume Reduction: Decreases the mass and volume of waste materials.

- Energy Efficiency: Microwaves can selectively heat waste materials, potentially reducing overall energy consumption.

Challenges:

- Equipment Complexity: Requires advanced materials and components that can withstand high temperatures and radiation.

- Power Demand: Microwave systems may consume significant amounts of electrical energy.

26. Chemical Recycling of Textiles

Concept:

Employ chemical processes to depolymerize synthetic and natural textile fibers from old clothing into monomers or other useful chemicals for reuse in manufacturing.

Implementation:

- Solvent Systems: Utilize solvents capable of breaking down fibers like polyester, nylon, or cellulose into their chemical building blocks.

- Reaction Vessels: Design reactors that can safely handle chemical processes in low gravity and contain volatile substances.

- Product Recovery: Purify and collect the resulting monomers or oligomers for use in synthesizing new materials.

Consideration of Lunar Environment:

- Chemical Handling: Strict protocols are necessary to prevent leaks or spills that could endanger crew members or equipment.

- Temperature Control: Chemical reactions may require specific temperatures, necessitating heating or cooling systems that function in extreme conditions.

- Radiation Protection: Chemicals and reaction products must be shielded from radiation to prevent degradation or unintended reactions.

Benefits:

- Material Recovery: Provides a source of raw materials for in-situ manufacturing, reducing dependency on Earth supplies.

- Waste Reduction: Converts waste textiles into valuable resources.

- Customization: Enables the creation of materials tailored to specific needs of the lunar mission.

Challenges:

- Safety Risks: Handling chemicals in confined spaces poses potential hazards.

- Resource Intensive: May require significant amounts of solvents and reagents, adding to payload considerations.

27. Advanced Plasma Pyrolysis

Concept:

Use plasma pyrolysis to break down a wide range of waste materials at the molecular level, converting them into syngas and inert slag.

Implementation:

- Plasma Reactors: Install compact plasma torches or arcs within reactors designed for the lunar environment.

- Waste Input: Feed various waste streams, including plastics, textiles, and organic matter, into the reactor.

- Byproduct Utilization: Capture syngas (a mixture of hydrogen and carbon monoxide) for use as fuel or in chemical synthesis; use slag as construction material.

Consideration of Lunar Environment:

- Low Gravity: Feeding systems must ensure consistent waste input without gravity-assisted flow.

- Thermal Insulation: Reactors operate at extremely high temperatures (over 3,000°C), requiring robust insulation to protect surroundings.

- Radiation Resistance: Equipment must be designed to withstand radiation without degradation.

Benefits:

- Versatility: Can process almost any type of waste, reducing the need for extensive sorting.

- Resource Recovery: Generates useful byproducts that can support other mission activities.

- Volume Reduction: Significantly decreases the mass and volume of waste needing storage or disposal.

Challenges:

- High Energy Consumption: Plasma processes require substantial power, necessitating reliable and efficient energy sources.

- Complexity and Maintenance: Advanced technology may increase the potential for mechanical issues and require specialized knowledge to repair.

28. Electrospinning of Recycled Fibers

Concept:

Transform waste textiles into new fibers using electrospinning, creating materials for clothing, filtration systems, or composite reinforcement.

Implementation:

- Fiber Solution Preparation: Dissolve waste textile materials in appropriate solvents to create a polymer solution suitable for electrospinning.

- Electrospinning Apparatus: Set up equipment that uses electric fields to draw ultra-fine fibers from the polymer solution.

- Fiber Collection: Collect spun fibers on a target, forming non-woven mats or aligned fiber structures.

Consideration of Lunar Environment:

- Low Gravity: Electrospinning relies on electric fields rather than gravity, making it well-suited for lunar conditions.

- Solvent Management: Closed systems are necessary to prevent solvent vapor release into the habitat.

- Radiation Effects: Equipment and materials should be shielded to prevent electrical interference or material degradation.

Benefits:

- Material Reuse: Converts waste into high-value fibers for various applications.

- Customization: Allows control over fiber properties by adjusting spinning parameters.

- Scalability: Equipment can be scaled based on mission needs.

Challenges:

- Solvent Use: Handling and recycling solvents adds complexity and potential safety concerns.

- Equipment Requirements: Precise control systems are necessary for consistent fiber production.

29. Thermoacoustic Energy Conversion from Waste Heat

Concept:

Harness waste heat from waste processing systems to generate electricity using thermoacoustic engines.

Implementation:

- Thermoacoustic Devices: Install engines that convert heat differentials into acoustic waves, which then drive electrical generators.

- Heat Sources: Connect thermoacoustic systems to waste processing units like incinerators or reactors.

- Heat Sinks: Utilize the cold lunar environment as a heat sink to maximize temperature differentials.

Consideration of Lunar Environment:

- Temperature Extremes: The significant difference between waste heat temperatures and the cold lunar environment enhances efficiency.

- Low Gravity: Thermoacoustic engines have no moving parts reliant on gravity, making them suitable for lunar application.

- Radiation: Electronic components must be shielded to prevent degradation from radiation exposure.

Benefits:

- Energy Recovery: Improves overall energy efficiency by converting otherwise wasted heat into usable electricity.

- Reliability: Fewer moving parts lead to lower maintenance requirements.

- Integration: Can be incorporated into existing waste processing infrastructure.

Challenges:

- Initial Setup: Requires precise engineering to optimize performance under lunar conditions.

- Heat Transfer Efficiency: Must ensure effective heat exchange in the vacuum of space.

30. Waste-Derived Bioplastics Production

Concept:

Produce bioplastics from organic waste materials, including food waste and biodegradable packaging, for use in 3D printing or manufacturing.

Implementation:

- Bioconversion Processes: Employ microorganisms or enzymatic reactions to convert organic waste into biopolymers like polylactic acid (PLA).

- Polymer Extraction: Develop methods to extract and purify biopolymers in the lunar environment.

- Product Fabrication: Use the bioplastics as feedstock for additive manufacturing or molding processes.

Consideration of Lunar Environment:

- Low Gravity: Bioreactors and extraction equipment must be adapted for microgravity fluid dynamics.

- Temperature Control: Biological and chemical processes require stable temperatures, necessitating thermal management systems.

- Radiation Protection: Shielding is necessary to protect biological agents from radiation damage.

Benefits:

- Resource Creation: Generates new materials from waste, reducing the need to transport plastics from Earth.

- Sustainability: Supports a circular economy within the lunar base.

- Versatility: Bioplastics can be used in a variety of applications, from tools to habitat components.

Challenges:

- Process Efficiency: Biological production rates may be slow and require optimization.

- Complexity: Integrating biological systems adds complexity to waste management infrastructure.

31. Freeze Concentration for Wastewater Treatment

Concept:

Use freeze concentration to treat liquid waste streams, separating pure water from contaminants by freezing.

Implementation:

- Freezing Units: Install systems that expose wastewater to lunar night temperatures, causing ice (pure water) to form while concentrating impurities in the remaining liquid.

- Ice Harvesting: Collect and melt the ice to retrieve clean water for reuse.

- Concentrate Handling: Process the concentrated waste for safe disposal or further treatment.

Consideration of Lunar Environment:

- Temperature Extremes: Leverage the extremely low temperatures during the lunar night to facilitate freezing without excessive energy input.

- Vacuum Conditions: Systems must prevent sublimation of ice in the vacuum, possibly through enclosed chambers.

- Low Gravity: Equipment must ensure proper separation and collection of ice and concentrate without gravity-dependent settling.

Benefits:

- Water Recovery: Efficiently recycles water, a critical resource for life support.

- Energy Efficiency: Reduces energy consumption compared to traditional distillation methods.

- Simplicity: Freeze concentration is a relatively straightforward physical process.

Challenges:

- Timing Constraints: Dependent on the lunar day-night cycle unless artificial cooling is used.

- Equipment Durability: Must withstand repeated thermal cycling and potential ice expansion stresses.

32. Integration of Artificial Intelligence for Waste Management Optimization

Concept:

Employ artificial intelligence (AI) and machine learning algorithms to optimize waste processing, resource allocation, and system maintenance.

Implementation:

- Data Collection: Use sensors and monitoring systems to gather real-time data on waste generation, processing efficiency, and equipment status.

- Predictive Analytics: AI models predict maintenance needs, processing bottlenecks, and resource shortages before they occur.

- Automation: Integrate AI with robotic systems to automate sorting, processing, and material handling tasks.

Consideration of Lunar Environment:

- Radiation Hardening: Electronic systems must be protected from radiation to prevent data corruption and hardware failures.

- Communication Delays: AI systems can operate autonomously, mitigating delays in communication with Earth.

- Energy Management: AI can optimize energy use across waste management systems, crucial in an energy-limited environment.

Benefits:

- Efficiency Improvement: Enhances system performance, reduces downtime, and optimizes resource use.

- Crew Support: Reduces the workload on astronauts, allowing them to focus on mission-critical tasks.

- Adaptability: AI can adjust operations based on changing conditions or unforeseen challenges.

Challenges:

- Complexity: Developing reliable AI systems for a unique environment requires significant investment.

- Reliability: Systems must be thoroughly tested to ensure they perform correctly under all conditions.

33. Electrostatic Waste Separation and Processing

Concept:

Utilize electrostatic forces to separate and process waste materials based on their electrical charge properties, which can be particularly effective in the Moon’s vacuum environment.

Implementation:

- Electrostatic Separators: Design systems that charge waste particles and use electric fields to separate them by material type (e.g., plastics, metals, organic matter).

- Low-Gravity Advantages: In low gravity, particles remain suspended longer, allowing for more efficient separation.

- Integration with Recycling: Sorted materials can then be directed to appropriate recycling or repurposing processes, such as melting plastics for 3D printing.

Consideration of Lunar Environment:

- Vacuum Conditions: The lack of atmosphere reduces interference with electrostatic forces, enhancing separation efficiency.

- Radiation: Equipment must be shielded to prevent static discharge caused by high-energy particles.

- Temperature Fluctuations: Systems should be thermally insulated to maintain consistent operation despite external temperature extremes.

Benefits:

- Efficiency: Electrostatic separation can be highly efficient and require less energy compared to mechanical sorting.

- Low Maintenance: Fewer moving parts reduce mechanical wear, which is advantageous in abrasive lunar dust conditions.

- Scalability: Systems can be scaled up or down depending on the volume of waste generated.

Challenges:

- Dust Mitigation: Lunar dust is highly charged and can interfere with the operation of electrostatic equipment, necessitating dust control measures.

- Material Compatibility: Not all materials may respond sufficiently to electrostatic charging, requiring hybrid systems.

34. Lunar Ice Mining for Waste Processing

Concept:

Use water ice found in lunar polar regions not only for life support but also as a medium for waste processing, such as hydrothermal treatments or creating aqueous solutions for chemical recycling.

Implementation:

- Ice Extraction: Mine lunar ice deposits and transport water to the habitat.

- Hydrothermal Processing: Use high-pressure, high-temperature water to break down waste materials, including plastics and textiles.

- Chemical Reactions: Dissolved waste can undergo chemical reactions to produce useful compounds or materials.

Consideration of Lunar Environment:

- Temperature Extremes: Water storage and processing equipment must prevent freezing or boiling due to temperature fluctuations.

- Low Gravity: Fluid handling systems need to operate effectively without gravity-driven flow.

- Radiation Protection: Shielding is necessary to prevent water radiolysis, which could produce unwanted reactive species.

Benefits:

- Resource Utilization: Maximizes the use of in-situ resources, reducing the need to transport water from Earth.

- Versatility: Water serves multiple purposes—life support, waste processing, and possibly fuel production.

- Waste Reduction: Converts waste into useful products, such as hydrogen and oxygen through electrolysis.

Challenges:

- Infrastructure Requirements: Ice mining and water processing facilities add complexity to the lunar base.

- Energy Demand: Processes like hydrothermal treatment and electrolysis require substantial energy input.

35. Advanced Membrane Technologies for Waste Separation

Concept:

Develop specialized membranes capable of separating waste components at the molecular level, using techniques like nanofiltration or reverse osmosis adapted for the lunar environment.

Implementation:

- Membrane Fabrication: Create membranes that can withstand lunar conditions, possibly incorporating lunar materials.

- Waste Processing Units: Design systems where liquid waste streams pass through membranes, separating contaminants from reusable water or solvents.

- Gas Separation: Use membranes to separate gases produced during waste processing, such as capturing carbon dioxide for life support.

Consideration of Lunar Environment:

- Low Gravity: Membrane processes rely on pressure differentials rather than gravity, making them suitable for lunar application.

- Temperature Control: Membrane performance can be sensitive to temperature; systems must maintain optimal conditions.

- Radiation Resistance: Membranes and supporting structures need to be resistant to degradation from radiation exposure.

Benefits:

- High Efficiency: Membrane processes can achieve high levels of separation with relatively low energy consumption.

- Compact Systems: Equipment can be designed to have a small footprint, conserving habitat space.

- Resource Recovery: Enables reclamation of water and other valuable components from waste streams.

Challenges:

- Membrane Fouling: Waste components can clog membranes, requiring cleaning or replacement strategies.

- Material Limitations: Developing membranes that maintain performance under lunar conditions is technologically challenging.

36. Magnetic Field Utilization for Waste Manipulation

Concept:

Employ magnetic fields to manipulate and process waste materials, particularly metals, taking advantage of the Moon’s lack of a substantial magnetic field to avoid interference.

Implementation:

- Magnetic Separators: Use magnets to extract ferromagnetic materials from waste streams.

- Eddy Current Separation: Apply changing magnetic fields to induce currents in non-ferrous metals, facilitating their separation.

- Magnetic Levitation: Use magnetic forces to transport or position waste materials within processing equipment.

Consideration of Lunar Environment:

- Vacuum Conditions: The absence of atmosphere reduces magnetic damping, potentially enhancing system efficiency.

- Low Gravity: Magnetic levitation can compensate for low gravity in material handling.

- Radiation Effects: Electronic components controlling magnetic fields must be shielded against radiation.

Benefits:

- Selective Separation: Efficiently separates metals for recycling and reuse.

- Non-Contact Handling: Reduces mechanical wear and contamination risks.

- Energy Efficiency: Magnetic systems can be energy-efficient compared to mechanical alternatives.

Challenges:

- Material Limitations: Only applicable to materials with magnetic properties.

- Dust Interference: Magnetic fields may attract or repel charged lunar dust, requiring mitigation strategies.

37. Lunar Regolith Bioleaching

Concept:

Utilize bioleaching processes to extract useful elements from waste materials and lunar regolith, employing microorganisms adapted or engineered to survive lunar conditions.

Implementation:

- Microorganism Selection: Identify or engineer microbes capable of bioleaching under low gravity, limited nutrients, and high radiation.

- Bioreactor Design: Create reactors that provide necessary conditions for microbial activity, including shielding and temperature control.

- Metal Recovery: Recover metals like iron, aluminum, or rare earth elements from waste and regolith for use in manufacturing.

Consideration of Lunar Environment:

- Radiation Protection: Microbes require shielding to prevent DNA damage from radiation.

- Temperature Control: Bioreactors must maintain temperatures conducive to microbial metabolism.

- Low Gravity Effects: Microgravity can affect microbial growth and biofilm formation, necessitating design adaptations.

Benefits:

- Resource Extraction: Supplements material supplies by extracting elements from in-situ resources and waste.

- Waste Reduction: Reduces waste volume by converting it into useful substances.

- Sustainability: Supports closed-loop systems and reduces dependency on Earth.

Challenges:

- Biological Risks: Containment is critical to prevent contamination of the habitat.

- Process Efficiency: Bioleaching rates may be slower under lunar conditions, requiring optimization.

38. Solar Radiation-Driven Photolysis

Concept:

Harness high-energy solar radiation on the Moon to break down waste materials through photolysis, decomposing them into simpler molecules without additional reagents.

Implementation:

- Exposure Chambers: Design facilities that expose waste materials to concentrated solar radiation, possibly using mirrors or lenses.

- Material Preparation: Spread waste materials thinly to maximize exposure and ensure efficient photolysis.

- Gas Collection: Capture gases released during decomposition for potential use or safe disposal.

Consideration of Lunar Environment:

- Abundant Solar Radiation: The lack of atmosphere increases the intensity of solar radiation, enhancing photolysis potential.

- Temperature Management: Systems must prevent overheating and protect against thermal damage.

- Radiation Safety: Ensure that harmful radiation does not pose risks to crew members or equipment.

Benefits:

- Reagent-Free Process: Eliminates the need for chemical reagents, simplifying logistics.

- Energy Efficiency: Utilizes solar energy, reducing reliance on electrical power.

- Waste Reduction: Breaks down waste into gases, significantly reducing volume.

Challenges:

- Limited to Lunar Day: Processes can only occur during the lunar day unless artificial light sources are used.

- Material Limitations: Not all waste materials may be susceptible to photolytic decomposition.

39. Origami-Inspired Foldable Structures for Waste Compaction

Concept:

Design foldable, origami-inspired structures that can compact waste materials efficiently, saving space and potentially creating structural components for the habitat.

Implementation:

- Foldable Containers: Develop containers that compress waste as they fold, reducing volume.

- Structural Use: Compacted waste within folded structures can serve as building blocks or radiation shielding.

- Material Design: Use materials that can withstand lunar conditions and incorporate waste materials into their composition.

Consideration of Lunar Environment:

- Low Gravity: Foldable mechanisms must function reliably without gravity-assisted movement.

- Temperature Fluctuations: Materials must maintain flexibility and integrity despite extreme temperatures.

- Radiation Resistance: Structures should resist radiation to remain durable over time.

Benefits:

- Space Efficiency: Reduces the physical space required for waste storage.

- Dual Purpose: Waste compaction units also contribute to habitat construction or protection.

- Psychological Benefits: Innovative designs may enhance crew engagement and morale.

Challenges:

- Mechanical Complexity: Moving parts may be prone to failure, especially with abrasive lunar dust.

- Material Fatigue: Repeated folding and unfolding could lead to material degradation.

40. Bioluminescent Systems for Waste Monitoring

Concept:

Use bioluminescent organisms or reactions as indicators to monitor waste processing efficiency, detect contaminants, or signal maintenance needs in a visually intuitive way.

Implementation:

- Bioluminescent Markers: Incorporate genes for bioluminescence into microorganisms used in waste processing.

- Sensor Integration: Design bioreactors or waste processing units where bioluminescence indicates system status.

- Data Collection: Use optical sensors to quantify light emissions, providing data for system optimization.

Consideration of Lunar Environment:

- Radiation Protection: Biological components need shielding to prevent damage.

- Temperature Control: Bioluminescent reactions may require specific temperatures to function efficiently.

- Low Gravity Effects: Microgravity could influence microbial activity and light production.

Benefits:

- Non-Invasive Monitoring: Provides real-time feedback without the need for complex instrumentation.

- Energy Efficiency: Bioluminescence requires minimal energy input compared to electronic sensors.

- Safety: Visual indicators can alert crew members to issues promptly.

Challenges:

- Biological Risks: Requires stringent containment to prevent unintended spread of engineered organisms.

- Reliability: Environmental factors may affect bioluminescent signals, necessitating calibration.

**41. Myco-Remediation Using Fungi

Concept:

Employ fungi capable of breaking down complex organic waste materials, including synthetic polymers found in clothing and packaging, through a process called myco-remediation.

Implementation:

- Fungal Selection: Identify or engineer fungal species that can degrade materials like plastics and textiles while surviving lunar conditions.

- Cultivation Systems: Design bioreactors or growth chambers providing suitable conditions for fungal growth, including moisture, nutrients, and temperature control.

- Byproduct Utilization: Harvest fungal biomass for use as soil amendments in plant growth systems or as a source of bio-based materials.

Consideration of Lunar Environment:

- Low Gravity: Fungal growth may be less affected by low gravity, but substrates must be secured to prevent detachment.

- Temperature Control: Growth chambers must maintain optimal temperatures insulated from external extremes.

- Radiation Protection: Fungal cultures need shielding from radiation to prevent DNA damage.

Benefits:

- Versatility: Fungi can degrade a wide range of organic materials, including some plastics.

- Resource Recovery: Converts waste into biomass that can be repurposed.

- Sustainability: Supports closed-loop life support systems by recycling nutrients.

Challenges:

- Containment: Preventing the spread of fungi is critical to avoid contamination.

- Efficiency: Degradation rates may be slow and require optimization.

**42. Programmable Matter and Self-Assembling Materials

Concept:

Utilize programmable matter or self-assembling materials that can change their properties or structure in response to external stimuli, allowing waste materials to be reconfigured into useful items.

Implementation:

- Material Design: Develop materials embedded with nanoscale components or smart polymers that can be reprogrammed.

- Stimulus Activation: Use stimuli such as temperature changes, magnetic fields, or electrical signals to trigger reconfiguration.

- Application: Repurpose waste materials into tools or structural components by altering their physical properties.

Consideration of Lunar Environment:

- Low Gravity: Self-assembly processes may be enhanced in low gravity but require study for reliable operation.

- Temperature Fluctuations: Materials must remain stable across extreme temperatures.

- Radiation Exposure: Programmable materials must resist radiation-induced damage.

Benefits:

- Flexibility: Materials can be reused multiple times for different purposes.

- Waste Reduction: Minimizes waste by enabling continual repurposing.

- Innovation: Advances material science applications in space exploration.

Challenges:

- Complexity: Developing such advanced materials is technologically challenging.

- Energy Requirements: Reconfiguration processes may require significant energy.

**43. Acoustic Levitation for Waste Manipulation

Concept:

Use acoustic levitation to manipulate and process waste particles without physical contact, aiding in sorting, separation, or assembly processes in low gravity.

Implementation:

- Acoustic Devices: Install ultrasonic transducers that create standing wave fields to levitate and move waste particles.

- Waste Processing: Manipulate particles for sorting based on size, density, or material properties.

- Integration: Combine with additive manufacturing, using levitated materials as feedstock.

Consideration of Lunar Environment:

- Low Gravity: Acoustic levitation is more effective, as particles are less influenced by gravity.

- Temperature and Pressure: Systems must function within pressurized habitats and maintain consistent performance.

- Radiation: Electronic components require shielding to prevent malfunction.

Benefits:

- Non-Contact Handling: Reduces contamination and mechanical wear.

- Precision: Allows for precise control of particle positioning.

- Innovation: Opens new possibilities for material processing.

Challenges:

- Energy Consumption: Acoustic systems may require substantial power.

- Scale Limitations: Effective primarily for small particles.

**44. Bioelectrochemical Systems for Waste Treatment

Concept:

Develop bioelectrochemical systems (BES), such as microbial electrolysis cells, that use microorganisms to degrade organic waste while generating hydrogen gas or other valuable chemicals.

Implementation:

- System Design: Create reactors where microbes oxidize waste at the anode, producing hydrogen at the cathode.

- Microorganism Selection: Use or engineer microbes efficient in low-gravity conditions and resistant to radiation.

- Integration: Utilize produced hydrogen as fuel or for life support systems.

Consideration of Lunar Environment:

- Low Gravity: Reactor designs must ensure effective microbe-substrate interaction without gravity-assisted mixing.

- Temperature Control: Maintain optimal temperatures for microbial activity.

- Radiation Protection: Shield systems to protect biological components.

Benefits:

- Resource Recovery: Generates useful gases from waste.

- Energy Production: Converts waste into energy-rich compounds.

- Waste Reduction: Reduces volume and mass of organic waste.

Challenges:

- System Complexity: Requires careful management and maintenance.

- Efficiency: May need optimization for lunar conditions.

**45. Phase Change Materials for Thermal Regulation in Waste Processing

Concept:

Incorporate phase change materials (PCMs) into waste processing systems to absorb or release thermal energy, stabilizing temperatures during processes sensitive to lunar temperature fluctuations.

Implementation:

- PCM Selection: Choose materials with melting points suitable for desired temperature regulation.

- System Integration: Embed PCMs in or around waste processing equipment to buffer against external temperature changes.

- Applications: Use in bioreactors, chemical processors, or storage units where temperature stability is critical.

Consideration of Lunar Environment:

- Temperature Extremes: PCMs help mitigate the impact of lunar day-night cycles.

- Low Gravity: Encapsulated PCMs prevent leakage or movement without gravity.

- Radiation Resistance: Materials must retain properties despite radiation exposure.

Benefits:

- Temperature Control: Enhances efficiency and reliability of waste processing.

- Energy Efficiency: Reduces need for active heating or cooling.

- Equipment Protection: Prevents thermal stress, extending equipment lifespan.

Challenges:

- Material Selection: Finding effective and safe PCMs for the lunar environment.

- System Complexity: Requires careful design for effective integration.

**46. Advanced Holographic Imaging for Waste Sorting

Concept:

Use advanced holographic imaging and optical sorting technologies to analyze and separate waste materials based on their spectral signatures.

Implementation:

- Imaging Systems: Employ hyperspectral cameras and holographic techniques to identify material composition.

- Automated Sorting: Integrate with robotic systems to sort waste based on imaging data.

- Data Processing: Use AI algorithms for real-time sorting decisions.

Consideration of Lunar Environment:

- Low Gravity: Sorting mechanisms must function effectively without gravity-assisted movement.

- Radiation Protection: Electronic systems require shielding.

- Dust Mitigation: Optical systems must be protected from lunar dust.

Benefits:

- Precision: Enables highly accurate waste segregation.

- Automation: Reduces crew workload and exposure.

- Adaptability: Can recognize new materials or waste stream changes.

Challenges:

- Technological Complexity: Advanced imaging systems may be sensitive.

- Energy Consumption: Requires power for imaging and processing.

**47. Synthetic Biology for On-Demand Material Production

Concept:

Use synthetic biology to engineer microorganisms that convert waste into various biopolymers or materials tailored to mission needs.

Implementation:

- Microbe Engineering: Modify organisms to produce specific compounds from waste substrates.

- Bioreactor Systems: Design flexible bioreactors capable of switching production modes.

- Product Utilization: Use produced materials for manufacturing, repairs, or 3D printing.

Consideration of Lunar Environment:

- Radiation Protection: Biological systems must be shielded.

- Temperature Control: Maintain conditions for microbial growth and synthesis.

- Low Gravity Effects: Mitigate impacts on microbial metabolism.

Benefits:

- Versatility: Supports adaptive mission planning.

- Waste Utilization: Converts waste into valuable resources.

- Sustainability: Reduces Earth supply dependency.

Challenges:

- Biosafety: Preventing contamination is critical.

- Complexity: Requires advanced technical expertise.

**48. Autonomous Swarm Robotics for Waste Collection and Processing

Concept:

Deploy a swarm of small, autonomous robots that collaborate to collect, sort, and process waste efficiently.

Implementation:

- Robot Design: Develop compact robots with sensors, manipulators, and communication systems.

- Swarm Intelligence: Program robots with algorithms for collective behavior.

- Task Specialization: Assign roles within the swarm, such as collection or processing units.

Consideration of Lunar Environment:

- Low Gravity Mobility: Robots must navigate and operate effectively, possibly using hopping or rolling.

- Radiation Protection: Electronics need shielding.

- Energy Supply: Efficient power sources are essential.

Benefits:

- Scalability: Swarm size adjusts to mission needs.

- Redundancy: Failure of individual robots doesn’t compromise the system.

- Efficiency: Operates continuously without human intervention.

Challenges:

- Communication Delays: Coordination must be robust against disruptions.

- Maintenance: Systems designed for minimal upkeep.

**49. Thermal Vacuum Pyrolysis Leveraging Lunar Environment

Concept:

Use the Moon’s vacuum and temperature extremes to perform pyrolysis of waste materials without complex reactors.

Implementation:

- Open Exposure: Place waste in containers exposed to sunlight for heating and then into shadowed areas for cooling.

- Material Decomposition: Thermal cycling breaks down organic materials.

- Gas Capture: Collect gases for use or disposal.

Consideration of Lunar Environment:

- Vacuum Conditions: Facilitates outgassing and reduces equipment needs.

- Temperature Extremes: Exploit natural fluctuations for processing.

- Radiation Exposure: Materials must withstand radiation.

Benefits:

- Energy Efficiency: Utilizes natural conditions.

- Simplicity: Minimizes equipment complexity.

- Waste Reduction: Decomposes waste into simpler compounds.

Challenges:

- Process Control: Difficult to regulate precisely.

- Material Handling: Systems needed to move materials safely.

**50. Solar Wind Utilization for Waste Ionization

Concept:

Capture and utilize solar wind particles to ionize waste materials, facilitating their breakdown or transformation.

Implementation:

- Solar Wind Collectors: Install devices that focus solar wind particles toward waste.

- Ionization Process: High-energy particles break molecular bonds in waste.

- Byproduct Management: Collect resultant ions or atoms for reuse.

Consideration of Lunar Environment:

- Exposure to Space: Systems must be outside the habitat.

- Radiation Safety: Shielding is necessary to protect crew.

- Low Gravity: Aids in dispersion and collection of particles.

Benefits:

- Energy Source: Utilizes natural energy without additional input.

- Novel Processing Method: Provides an unconventional approach.

Challenges:

- Efficiency: Low particle density may limit process rate.

- Safety Risks: Managing high-energy particles is challenging.

51. Biodegradable Construction Materials from Organic Waste

Concept:

Transform organic waste, including food scraps and biodegradable packaging, into biodegradable construction materials that can be used for temporary structures or insulation within the lunar habitat.

Implementation:

- Biopolymer Production: Use organic waste to produce biopolymers like polylactic acid (PLA) through fermentation processes.

- Material Formulation: Combine biopolymers with lunar regolith to create composite materials with enhanced mechanical properties.

- Manufacturing Techniques: Employ 3D printing or molding to fabricate building components, panels, or insulation materials.

Consideration of Lunar Environment:

- Low Gravity: Adapt manufacturing equipment to function effectively without gravity-assisted processes.

- Temperature Extremes: Ensure materials maintain integrity across the lunar temperature range, possibly by incorporating additives that enhance thermal stability.

- Radiation Exposure: Materials should be designed to resist degradation from radiation or include protective coatings.

Benefits:

- Resource Utilization: Converts waste into valuable building materials, reducing reliance on Earth supplies.